With high efficiency, high stability and high durability JBOSS provides customers with products with high cost-effective.

DM Series | Precision injection molding machine

JBOSS launched DM series precision injection molding machine,The rigidity of the locking and injection mechanism is strengthened,With a new generation of high-speed computers,Combined with full digital bus communication technology, international specifications communication interface, international first-line brand components, can achieve more fine process control, full closed-loop precision control of injection process, the interconnection of peripheral equipment, is committed to providing users with cost-effective, high durability, intelligent, digital precision injection molding machine, Positioning production of high quality plastic products.

Advantages of injection molding machines

High rigidity clamping mechanism

High rigidity clamping mechanism

It uses the center press clamping design, the center of the platen is thickened, which improves the molding accuracy of the product and reduces the product clamping line.

Fork type Toggle

Fork type Toggle

The strong fork type toggle reduces the wear of the clamping mechanism parts, reduces the stress and deformation, and makes the main parts of the mold clamping have a longer life.

Intelligent Energy Durable

Intelligent Energy Durable

①Intelligent motion control software and hardware, low-pressure mold

protection, one-key fool-style mold opening and closing settings, process

settings are simpler, the mold clamping mechanism opens and closes the

mold quickly and smoothly, reducing mechanical loss.

② Full digital bus control system, easy to use, extensible, and supports

the interconnection of the extended equipment and other devices.

③International standard communication interface, easier to achieve

automation, increase per capita productivity.The Linux system has better

compatibility and can achieve more third-party software integration.

Precision And Stability

Precision And Stability

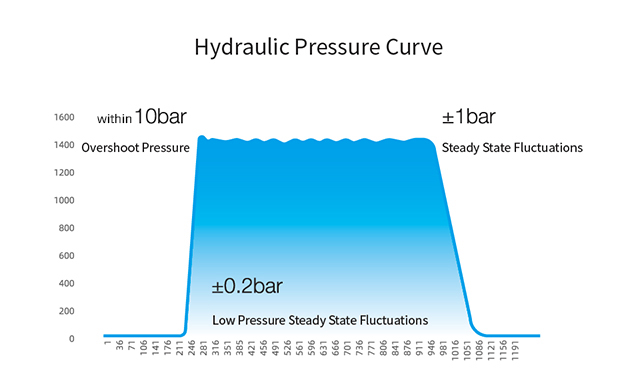

The injection pressure is higher , the maximum injection pressure setting is 175, For models below DM500, A screw injection pressure is generally greater than 2200bar.High injection pressure, The Ethercat communication technology, smaller interference, more refined process control, better product qualification rate;Independent temperature control module, accurate barrel temperature control, strong injection mechanism to ensure stability.