Customer-focused, and Striver-oriented.

3C Electronic

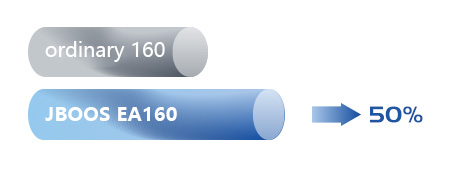

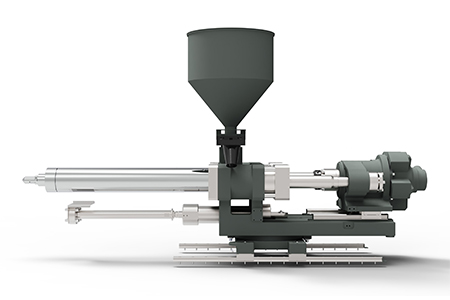

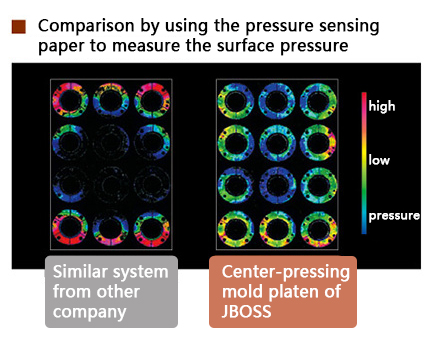

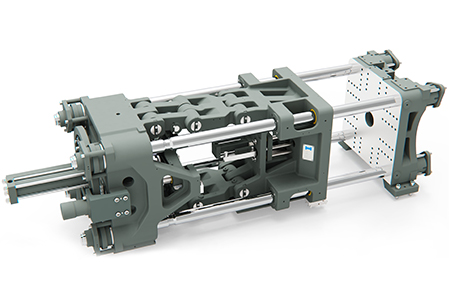

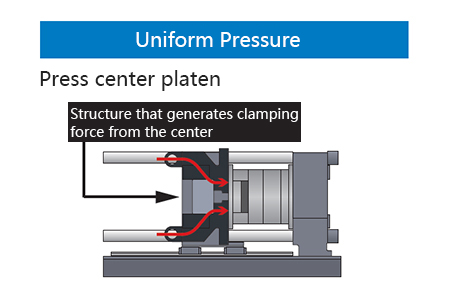

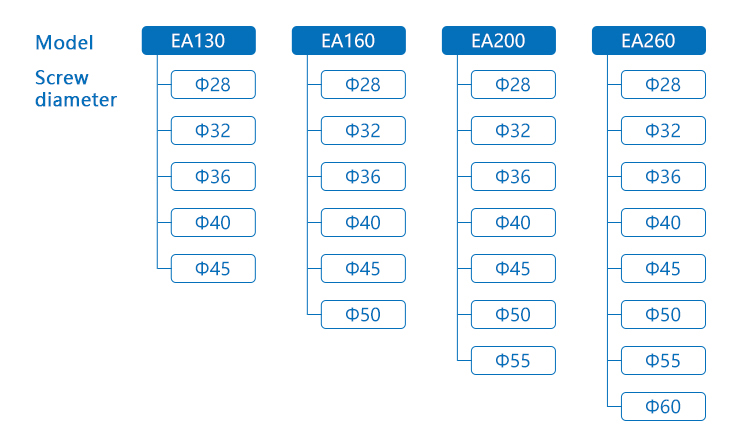

3C precision electronics industry, such as mobile phone accessories products based on PC, elastomer, ABS+PC and other raw materials,which have the characteristics of thin wall, light weight, small size and bright surface, so the injection molding machine is required to have strong clamping system, high injection pressure and high injection rate. , The molding cycle is fast, precise and stable.