1. High response and high speed injection

It is necessary to adopt the fast response and high speed injection unit to full fill the plastic into to mold completely before the plastic become solid for thin wall plastic products.

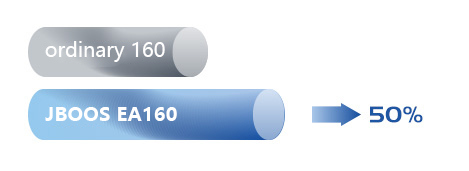

Comparation of injection speed

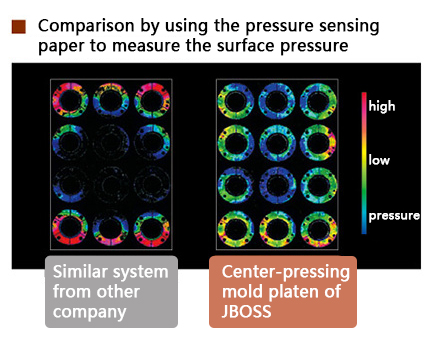

2. Filling in mould is smooth and even

“Easy going” injection create the condition of production stability, shorten the cooling time and cycle time.

JBOSS EA series high efficiency IMM reduce the mold pressure a lot compared with other general molding machines when the plastic temperature similar.

In other words, in the condition of mold pressure constants achieve lower temperature forming and shorten the cooling time, scorch and exhaust gas be restrained effectively at the same time.

The precision control to screw through the pressure and flow exchange let injection is uniform and smooth, prevent the short shot and deckle edge happen. The even pressure reduces the clamping force, the rate of short shotting, warping and deformation closes to zero.

3. Reduce bad appearance

The above-mentioned good filling and clamping performance greatly reduces the short shot, burr, warpage, shrinkage and other undesirable phenomena.

4. Reduce spray defects

After the defects such as fusion lines are reduced, the number of spraying can also be reduced. In addition, it is easier to reduce the defective rate of spraying when there is no impurity oil trace.

5. Simplified mold maintenance

The generation of residues in the mold cavity is reduced, thereby extending the maintenance cycle of the mold.