With high efficiency, high stability and high durability JBOSS provides customers with products with high cost-effective.

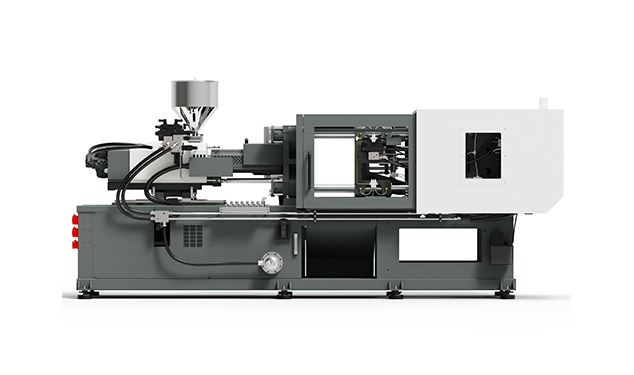

EA Series | High performance injection molding machine

In-depth interpretation of the five core values, strong support for user's profit growth

Senior experts with more than Twenty-Year experience in R&D, production and sales who take 3 years to create an efficientservo injection molding machine as per users’demand, and which also realizing the full closed-cycle precision control of

the injection process, committed to improving the capacity and qualified rate of products, reducing energy consumption and

production costs for users,positioning production of high quality plastic products.

Advantages of injection molding machines

Wide Range Of Applications

Wide Range Of Applications

Larger specifications, strong power and sensitive

response speed, adapt to high-pressure, high-speed,

low-pressure, low-speed and other product process

requirements. Modular design of the mechanical

structure, large hydraulic servo power, precise electronic

control system, flexibly meet the following industry

applications:

①Household products which requiring high efficiency

and energy saving;

② Electronic products, Packaging parts which requiring

high injection speed, small injection volume, or multi-

cavity;

③Home Appliances and auto parts and other industry

which requiring to provide flexible, efficient and stable

solutions for various process technologies.

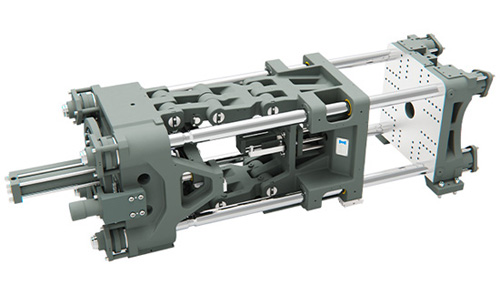

Reliable And Durable

Reliable And Durable

The machine structure is simple and reliable, strengthens the clamping and injection mechanism, strengthens the machine frame, which adapts to high-pressure and high-speed production.

Intelligent

Intelligent

① Intelligent motion control software and hardware, low-pressure mold

protection, one-key fool-style mold opening and closing settings, process

settings are simpler, the mold clamping mechanism opens and closes the mold

quickly and smoothly, reducing mechanical loss.

② Full digital bus control system, easy to use, extensible, and supports the

interconnection of the extended equipment and other devices.

③International standard communication interface, easier to achieve

automation, increase per capita productivity.The Linux system has better

compatibility and can achieve more third-party software integration.

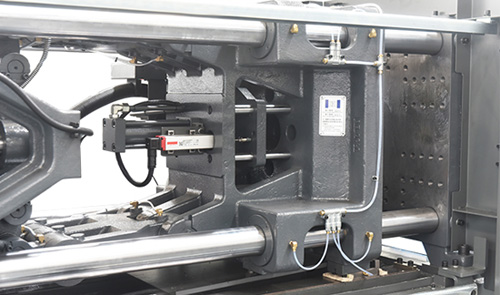

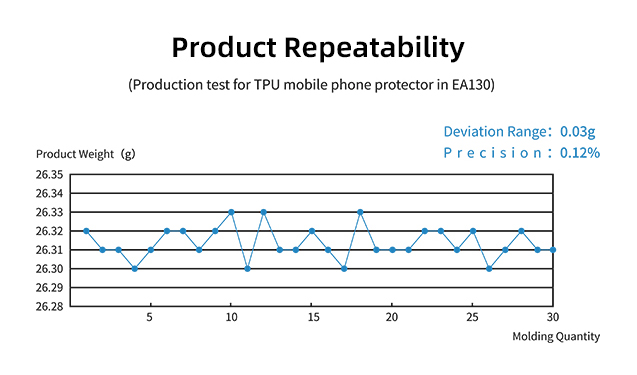

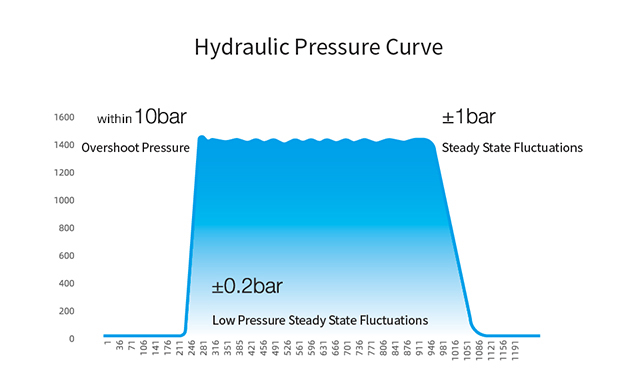

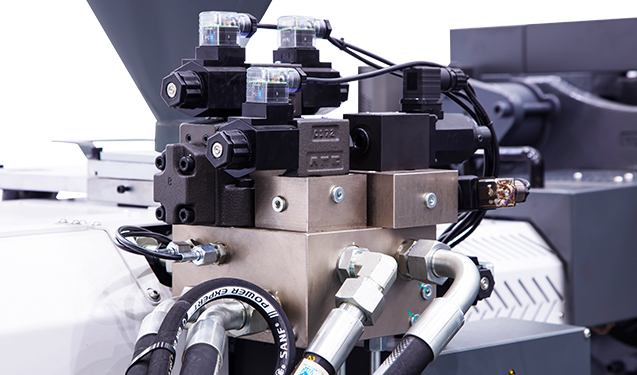

Precision And Stability

Precision And Stability

The Ethercat communication technology, smaller interference, more refined process control, better product qualification rate; Independent temperature control module, accurate barrel temperature control, strong injection mechanism to ensure stability.

Energy Saving

Energy Saving

With strong power, double-layer linear guide injection, production efficiency is increased by 10%-50%, production cost is reduced, and energy saving is 5%-10%; the injection speed increase function can be activated for specific applications, and the injection speed can be Increased by 10%-35% based on the standard machine.