Electricity limited, rising electricity bills, environmental protection, and more and more demand for saving electricity.

JBOSS EA series injection molding machines use low-pressure injection and low-clamping force forming technology and intelligent control technology, which can realize low-energy-consumption injection molding.

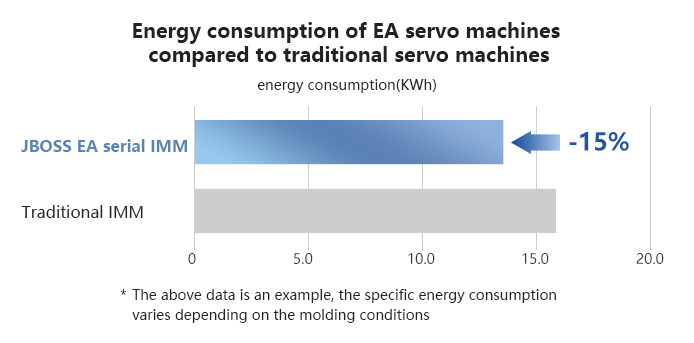

Effect

Compared with traditional machines, electricity consumption has dropped significantly due to hardware upgrades.

Methods through hardware and software upgrade to reduce energy consumption

1.Reduce power consumption by reducing the motion inertia of components.

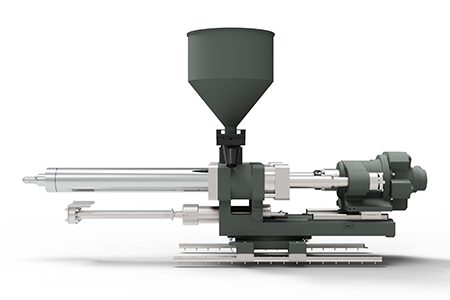

Double-layer linear guides injection unit as standard, reduce power consumption by reducing the sliding resistance of the guide rail during injection and storage, and improving the response speed.

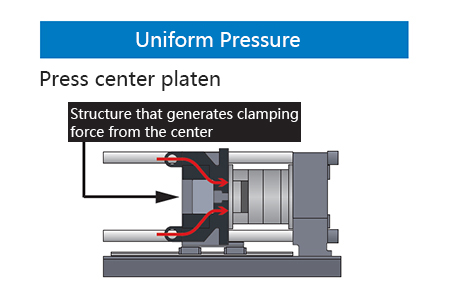

2.Reduce power consumption by molding with lower clamping force

Using the pressure center clamping structure of the JBOSS injection molding machine can improve the cavity balance problem caused by multi-cavitys, shorten the molding cycle while ensuring the quality, complete thin-wall molding, and reduce the clamping force, injection pressure, and energy consumption.

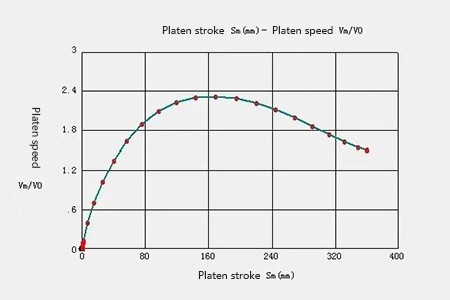

3.Reduce power with intelligent programs

JBOSS EA series IMM apply intelligent motion control software and hardware, one button control for mold open and close setting, intelligent injection motion and intelligent clamping motion control let the dry cycle more fast and movenment more stable, achieve close-loop control for mold opening position, improve the efficiency and reduce the ware of mechanical part, improve the life of mold and machine, and save power consumption.

4.Reduce power consumption with optional infrared heating coil

JBOSS provides the option of installing infrared heating coils for some applications. The high efficiency of electric heating exchange is 99.8%, and the heating part can save energy more than 30%.