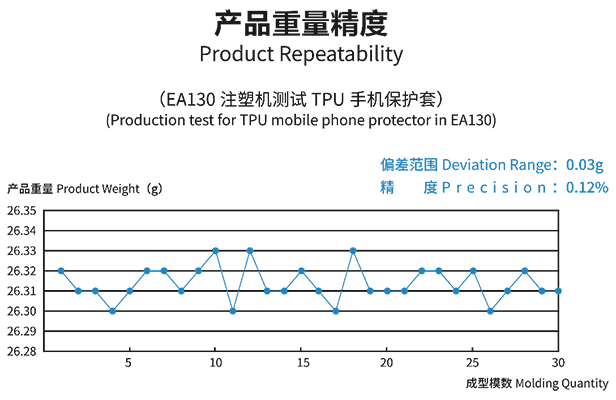

Usually precision injection molding machines have two indicators: one is the repeat deviation of product size; the other is the repeat deviation of product weight. The former is difficult to compare due to the size and thickness of the product; the latter represents the comprehensive level of the injection molding machine.

Generally, the weight repetition error of an ordinary injection molding machine is about 0.5%-1%, a better machine can reach 0.8%, and less than 0.5% is a precision machine. Generally, the injection molding machine produced in China is about 0.5%, and less than 0.3% is an ultra-precision machine. machine. As mentioned above, the precision injection molding machine requires that the dimensional accuracy of the product is generally within 0.01 ~ 0.001mm.

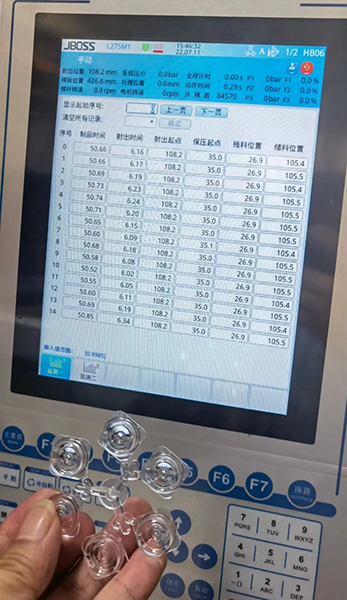

According to the actual measurement, Jboss EA130 injection molding machine produces mobile phone protective cases, and the weight accuracy of the product is 0.12% (ie 0.03 grams), and the accuracy is close to the imported European and Japanese injection molding machines, filling the accuracy gap between the European and Japanese injection molding machines and the Chinese domestic injection molding machines.

With the increasingly fierce competition in the plastic product market and the more and more serious profit squeeze , to speed up the molding cycle, and become an important way out for the transformation of plastic product manufacturers.

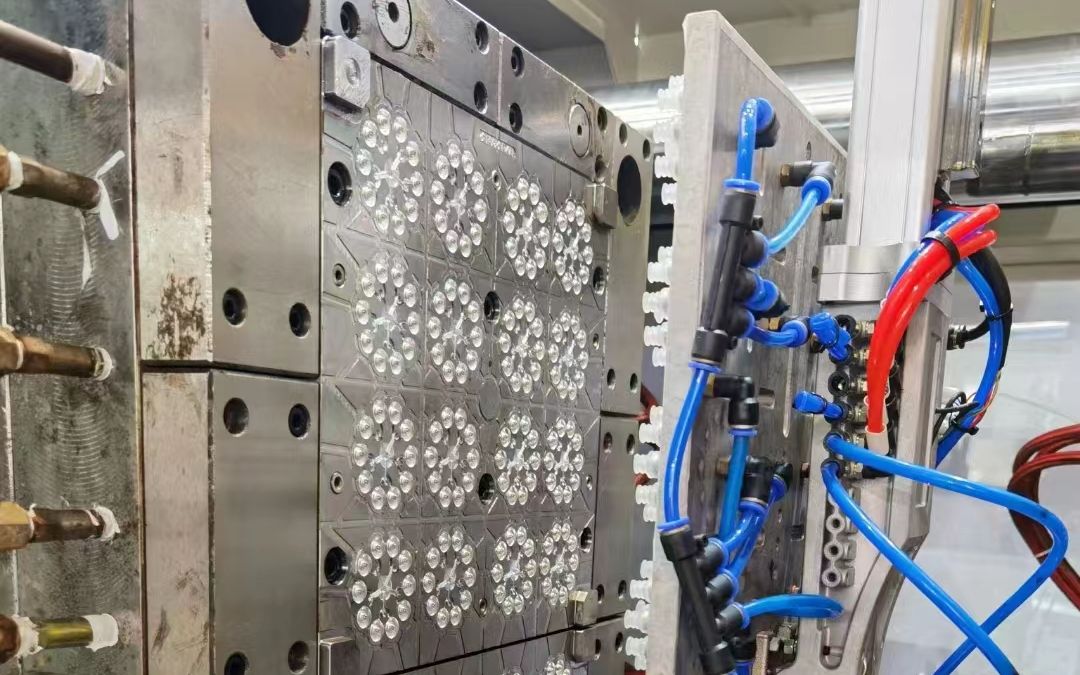

Optical lenses and components are divided into refraction products and reflective products, which are ultra-precision products in the plastic product industry. Due to the high requirements for light refraction and reflection, the pressure stability and speed stability of injection molding machines are extremely high. Require.

Optical lenses are generally produced with PC or PMMA. In addition to not yellowing and black spots, optical instruments must be used to test the brightness and refraction. Only when all the indicators are met are qualified. Therefore, the yield rate of lens production is the most extreme embodiment of the precision and stability of the injection molding machine.

A user in Guangdong owns about 200 injection molding machines, which is at the leading level in the global optical lens industry. In the past, Japanese brand electric injection molding machines were used to produce optical lenses. Now, some of them use Jboss injection molding machines with 128-cavity molds to produce optical lenses. The unit weight of this product is less than 1 Gram, its excellent low-speed linearity, super overload-resistant servo system, has been recognized by users:

The monitoring screen of the 128-hole optical lens produced by Jboss injection molding machine